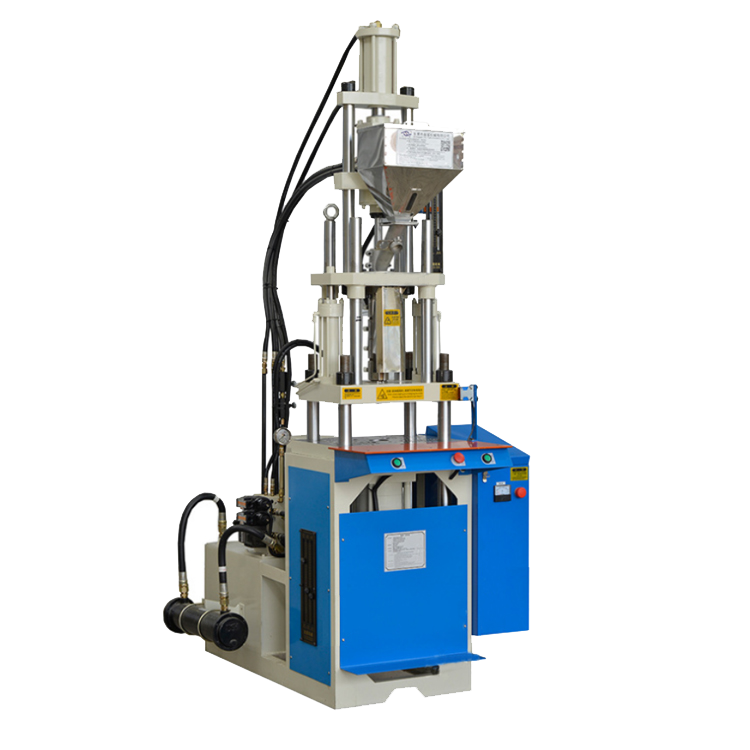

Lab Small Plastic Vertical Injecting Molding Machine

Model

NG-3211

MOQ

1 Set

Lead Time

3-15 Working Days

Country of Origin

China

Package

Standard Export Wooden Box

OEM & ODM

Support

描述

用户评论 (0)

描述

Summary:

Plastic injection moulding is the process of melting plastic pellets (thermosetting/ thermoplastic polymers) that once malleable enough, are injected at pressure into a mould cavity, which fills and solidifies to produce the final product.

Features:

1.Vertical mold opening and vertical injection, suitable for insert molding.

2, Nitrided mast, material tube, high torque night pressure motor drive, multi-stage injection pressure, good plasticizing performance.

3, Direct pressure mother-mother lock cylinder design, rapid mold clamping, low-pressure safety mold clamping, abnormal automatic mold opening, multiple pressure control, high safety, improve mold life.

4, Electrical warranty device, no mistakes occur, maintenance operators safe.

5, Automatic fault display, maintenance is quick and easy.

6, Electronic control, night pressure face using brand-name parts, quiet, precise and durable.

7, Multi-stage temperature control, multi-stage injection pressure, injection speed, back pressure stepless adjustment, suitable for precision plastic parts molding.

Specifications:

Screw Diameter

Mm

26

28

30

Injection Pressure

kg/cm²

1530

1278

886

Theoretical Shot Volume

cm³

61

70.8

81

Max.Shot Weight(ps)

g

56

64

74

Safe Shot Weight(ps)

OZ

2

2.27

2.6

Max.Shot Weight(ps)

cm³/sec

57

66

75.5

Injection Rate

mm

115

Screw Speed Max.

rpm

0-205

Nozzle Comtact Force

Tons

4.45

Nozzle Retraction Stroke

mm

170

Clamping Force

Tons

35

Platen Size

mm

540*380

Distance between tie bere

mm

375*205

Min.Mold Height

mm

158/58

Opening Stroke

mm

180

Max.Open Daylight

mm

338/238

Ejetor Force

Tons

1.3

Ejetor Stoke

mm

35

Max.Hydaulic Pressure

kg/cm²

140

Pump Output

l/min

34.5

Oil Resservoir Capacity

l

100

Cooling Waer Consumption

l/hr

400-600

Pump Motor Power

KW/HP

3.75/5.5HP

Berrel Heating Power

KW

2.4

Total Electricity

KW

6.3

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

Laboratuvar küçük plastik dikey enjekte kalıplama makinesi

Marka:

SKU: CM-R3ZWT

Kategori: Analiz - Test

Güvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.