描述

Items

Servo Universal Tensile Testing Machine

Model

NG-101

Max. Capacity

10, 20, 50, 100, 200, 500, 1000, 2000Kg (Optional)

Unit

G, KG, N, LB can be exchanged

Accurate Grade

0.5grade

Display Device

PC

Resolution

1/250,000

Effective Accuracy

±0.2%(0.5grade)

Max. Effective Stroke

800mm (column 143mm)

Speed Range

0.05-500mm/min (adjustable )

Motor

Servo Motor + High Precise Ball Screw

Elongation Accuracy

0.001mm

Power

AC220V, 50/60HZ(custom-made)

Standard Accessories

Tensile Clamp (According to your test samples), English Computer,

English Software CD

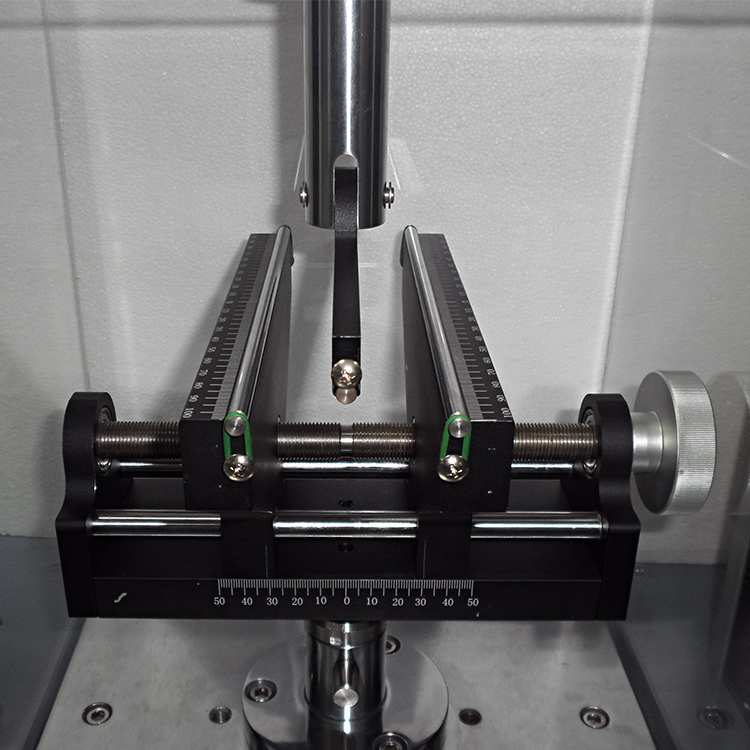

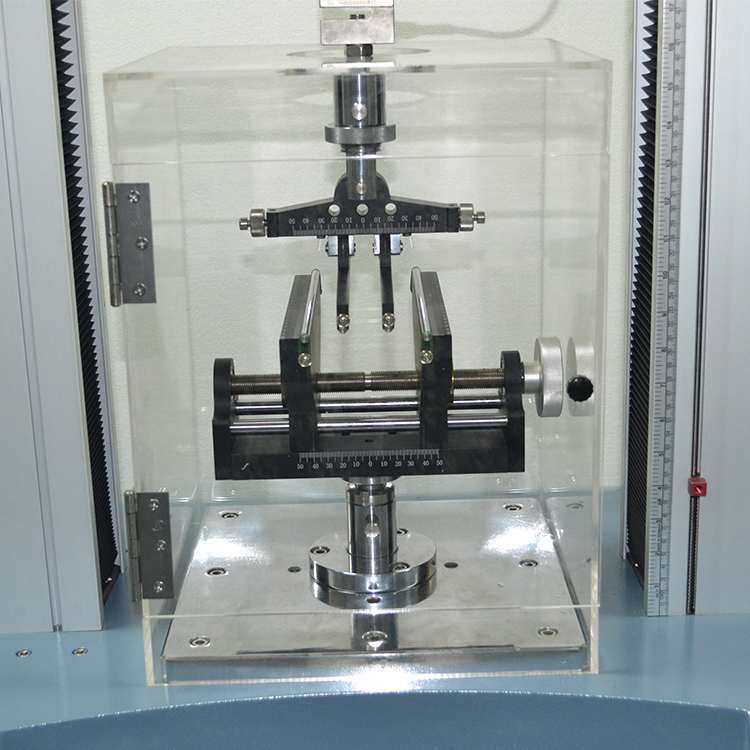

This tester is applicable to analysis and research of static physical performance test on phone glass,tablet computer glass,liquid crystal glass,touch sensor glass,toughened glass with three-point,four-point bending and elongation test;can do experiments according to International standard like GB,DIN,ISO,JIS and ASTM as well as furnish information(like JC/T676-1997glass material bending test methods,BS EN 1288-3-2000 architectural glass and determination of glass bending strength);test data is in form of dynamic curve display;it automatically obtain maximum force,maximum deformation,bending strain,bending strength,bending modulus,,compression strength,compression force,etc.

Elastic modulus in bending (i.e., flexural modulus), stress-strain behavior, and failure limits in bending all can be obtained using the simple sample geometry of a 3-point bend test. ASTM D790 or ISO 178 covers flexural properties for plastics; ASTM E855 is used for properties of flat metallic spring materials; ASTM C1684 or C1161 covers 3-point bend testing of ceramics. Four-point bend testing is similar, the major difference is that the addition of a fourth loading point brings a much larger portion of the beam to the maximum stress.

Typical applications:

Glass 3-points bending test

Glass 4-points bending test

Glass compressive strength test

Metal / sheet tensile test

Rubber / plastic tensile test

Metal / plastic bending test

Tape 900/1800 peel strength test

FPC pull test

Beverage packaging compression / bursting force test

The product holding force (Constant) Test

Low cycle fatigue (loop) test

Metal timber three-point bending test

Environmental plywood adhesive force test

The composite woven packaging with strength test

Features:

High-precision:

Use Panasonic AC servo motor to drive, and ABBA high precision ball screw for transmission, with high precision explosion-proof LOADCELL from U.S. TRANSCELL, the force accuracy can be ± 0.25%, the displacement accuracy is up to 0.001mm.

High intelligence:

Automatically determine the fracture, automatic return, the force units are free to switch languages switchable: Simplified / Traditional Chinese, English. Load – displacement, load – time, displacement – time stress – strain, strain – time, stress – time multi-curve analysis.

Test report:

Statements developing is based the Crystal Reports10.0 version, can automatically calculate the strength, elastic modulus E RP0.2 ReL, ReH, elongation, content can be freely altered ,curve automatically generated. Can be exported to Excel, PDF, HTML and other formats.

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

Cep telefonu cam 3 puan bükülme 4 puan bükme test cihazı, telefon kapağı cam 3pb 4pb test cihazı

Marka:

SKU: CM-JBG92

Kategori: Analiz - Test

Güvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.