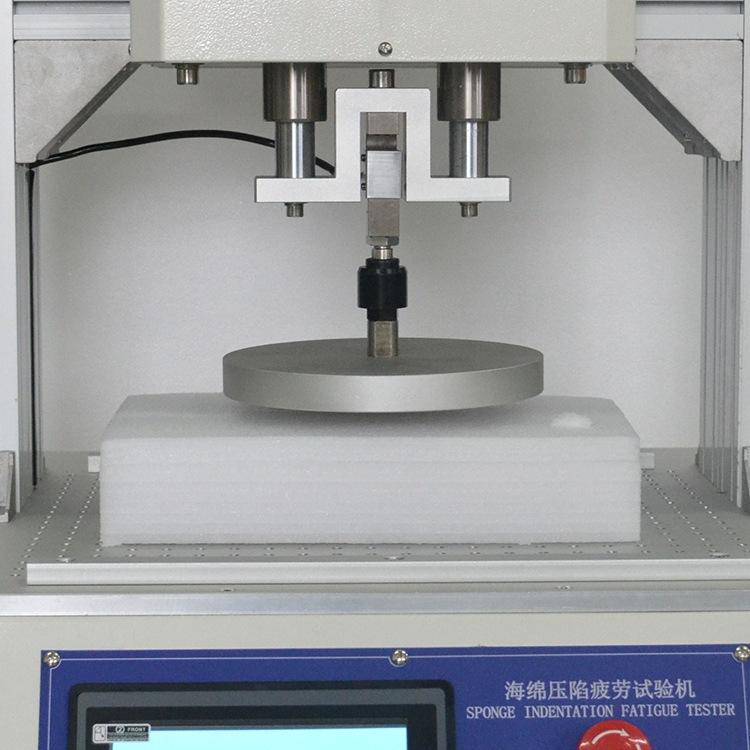

Sponge Indentation Fatigue Tester, Foam Sponge Indentation Hardness Tester

Model

NG-174

MOQ

1 Set

Lead Time

3-15 Working Days

Country of Origin

China

Package

Standard Export Wooden Box

OEM & ODM

Support

描述

用户评论 (0)

描述

Summary:

Sponge foam compression hardness tester is used to determine the indent hardness of porous elastic

materials.The foam samples of polyurethane foam can be tested according to the national standard.In

addition, it can also be used to measure the specified compression hardness of seat foam produced (such as

backrest, cushion foam, etc.), and accurately measure the compression hardness of seat foam parts.

Test Theory:

Sponge foam sag hardness test on the sample is placed, the press plate, pressure plate to speed down compression are rules on the size of the sample to the national standards of A method (B, C) by concavity, its load on the yuan will be treated as sensing pressure feedback to the controller and display, sample measured sponge, foam and other material, such as hardness.

Features:

Automatic reset: the system will automatically reset after the computer receives the test start instruction.

Automatic return: the sample will return to its original position after breaking.

Automatic gear shift: different gears can be switched according to the load size to ensure the measurement accuracy.

Change speed: this machine can change the test speed arbitrarily according to different samples.

Display and value verification: the system can achieve accurate calibration of force value.

Control method: according to test requirements, test force, test speed, displacement, strain and other test methods can be selected.

Multi-use one machine: equipped with sensors of different specifications, multi-use one machine.

Curve traversal: after the test, the force value and deformation data of the test curve can be found out arbitrarily with the mouse and analyzed.

Display: dynamic display of data and curve test process.

Results: the experimental results can be accessed and the data curve can be analyzed.

Limit: programmed and mechanical limit.

Specifications:

Control mode

Touch screen control

Induction mode

precision load cell

Capacity

200kg

Unit switching

Kg, N, LB

Upper pressure plate

200mm in diameter, R1mm at the bottom

Lower platform

420 x 420mm, with a diameter of 6mm and a spacing of 20mm

Maximum stroke

200mm

Test speed

100 + / 20mm/min

Power source

servo motor

Transmission mode

precision ball screw

Electrical source

220V, 50Hz/60Hz

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

Sünger Girişim Yorgunluk Test Cihazı, Köpük Sünger Giriş Sertlik Test Cihazı

Marka:

SKU: CM-GM1P1

Kategori: Analiz - Test

Güvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.