Specification

No. of spindles

1

Wire size

0.02-0.1 mm

Max coil width

30 mm* larger upon request

Max coil diameter

15 mm

Bonding method

Wire bonding via thermocompression technology, for start and end lead connection onto chip pad

Spindle speed

up to 9,000 rpm

Spindle position accuracy

+- 0.1°

Guide head drive motor

CNC 6 Axis AC servo motor synchronizing control

Control system

Windows interface PC with USB connector & DVD ROM

Interface

RS232 or USB

Touch screen

15 inch

Air supply

6 Bar

Power supply

single phase 220V +-10% 50Hz

Power consumption

< 4 kwA

Weight

180 Kg

Dimensions (cm)

700(W) x 800(L) x 1500(H) – excluding wire spool stand

Description:

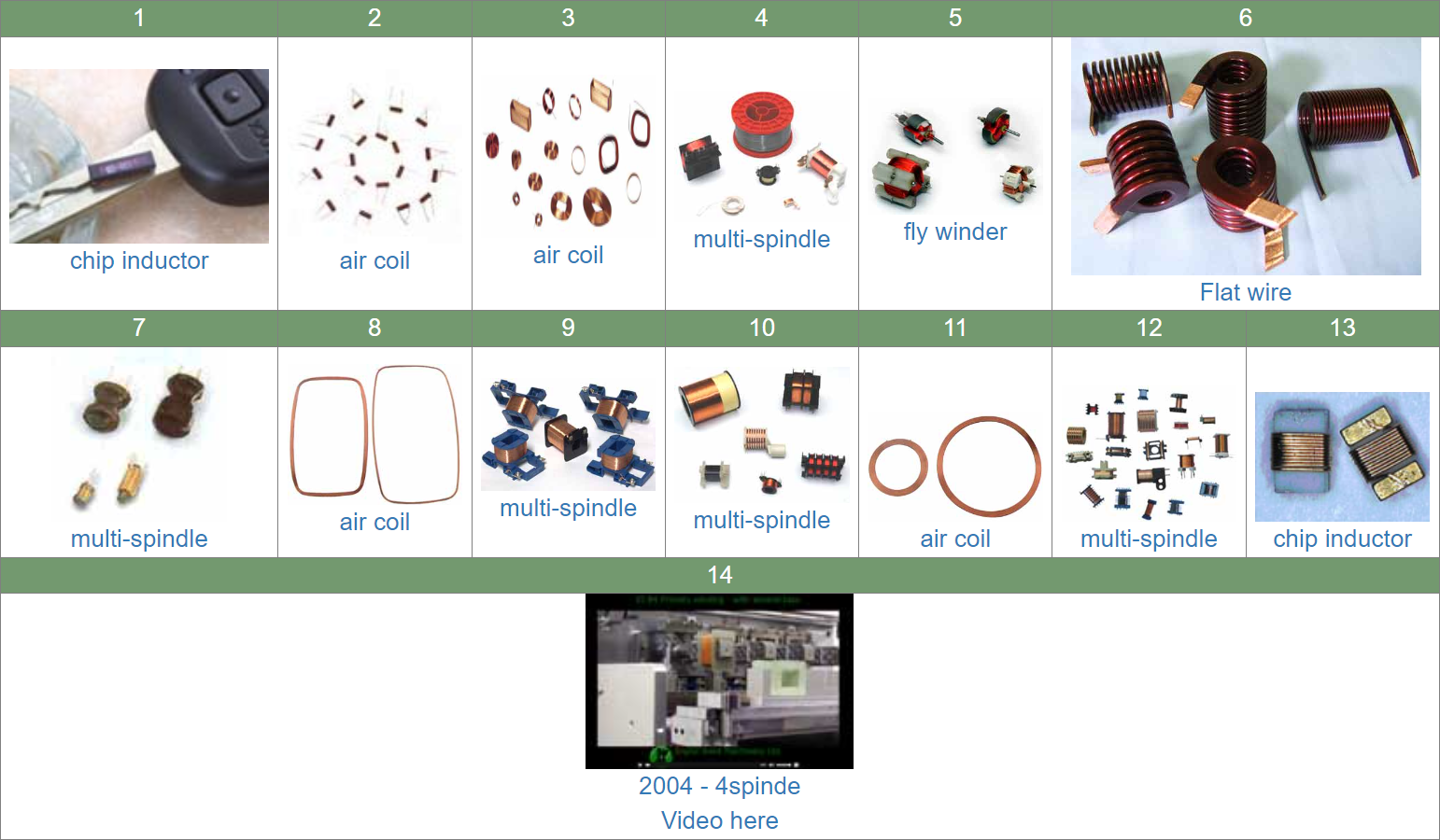

Chip inductor winding machine providing fully automatic production of SMD inductors in large volume, typically 0402, 0603, 0805, 1008 chip sizes and other ferrite-wound products.

Main features:

Bowl feeder for ferrite components, wire cutting on tooling clamp, guide over start pad on ferrite, weld, winding, guide over end pad, weld, cut end wire, remove ferrite, unload - all performed in a fully automatic process.

Built-in welding system to connect start and finish leads.

The wire guide movement can be freely programmed in all 3 axes (X, Y, and Z).

15 inch touch screen for easy setup, with industrial PC, network card, USB memory for program storage and simple backup.

Wire tensioner with magnetic braking provides constant tension.

Easy to change tooling and machine set-up recalled from the onboard computer when changing product.

Options:

Load and unload to tape and reel.

Various tooling can be designed depending on component requirements.

Customised accessories to suit your application