描述

Items

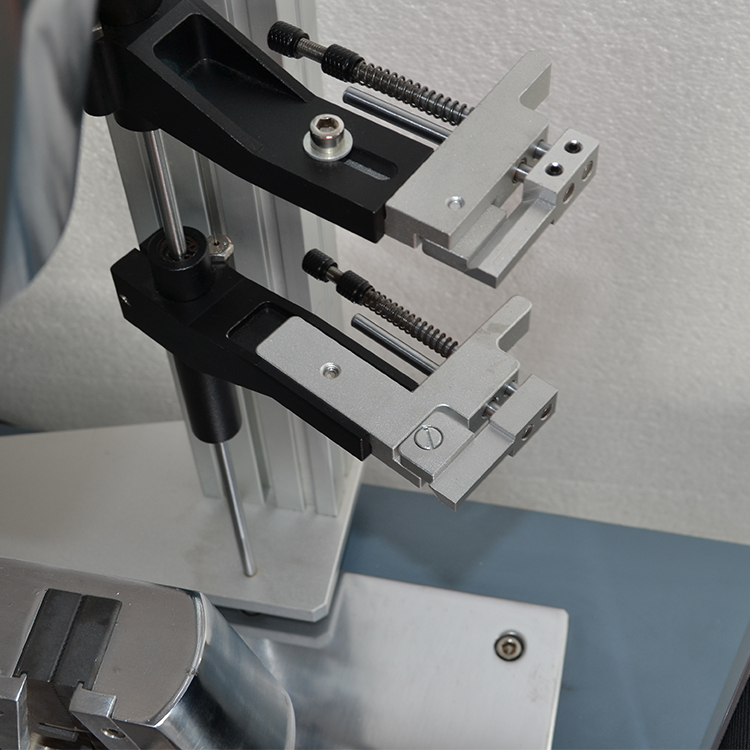

Servo Universal Tensile Testing Machine

Model

NG-101

Max. Capacity

10, 20, 50, 100, 200, 500, 1000, 2000Kg (Optional)

Unit

G, KG, N, LB can be exchanged

Accurate Grade

0.5grade

Display Device

PC

Resolution

1/250,000

Effective Accuracy

±0.2%(0.5grade)

Max. Effective Stroke

800mm (column 143mm)

Speed Range

0.05-500mm/min (adjustable )

Motor

Servo Motor + High Precise Ball Screw

Elongation Accuracy

0.001mm

Power

AC220V, 50/60HZ(custom-made)

Standard Accessories

Tensile Clamp (According to your test samples), English Computer,

English Software CD

Overview:

ASTM D412 covers two test methods: Method A and B. Method A is a common guideline for evaluating the tension properties of dumbbell samples of vulcanized thermoset rubbers and thermoplastic elastomers. Method B covers procedures to evaluate the tension properties of flat ring samples of vulcanized thermoset rubbers and thermoplastic elastomers. ASTM D412 gives you the choice of six specimen geometries and cutting die. The standard calls for specimens which have not been pre-stressed to be measured for:

• Tensile stress

• Tensile stress at a given elongation

• Tensile strength

• Yield point

• Ultimate elongation

ASTM D412 Test Method A

Method A for ASTM D412 is a common test for dogbone and strip samples of rubber and elastomers. Tensile stress, yield point, and tensile strength are based on the original cross-sectional area of a uniform cross-section of the specimen. Measurement of tensile set is made after a previously unstressed specimen has been extended and allowed to retract by a prescribed procedure.

Method A can be performed using a universal testing machine capable of constant rate of extension (CRE) control. To determine tensile stress, tensile strength and yield point, place your dumbbell-shaped sample in the grips. The rate of grip separation should be 500 to 50 mm/min (20 to 2 in./min). Start the machine and note the distance between the bench marks. Record the force at the elongation specified for the test and at the time of rupture. The elongation measurement is made preferably through the use of an extensometer.

Test Procedure

1. Cut or injection mold your material into a “dumbbell” shaped specimen.

2. Load the specimen into tensile grips.

3. Attach the optional extensometer to the sample

4. Begin the test by separating the tensile grips at a speed of 20 inches per minute

5. End the test after sample break (rupture)

Analysis obtained:

1. Stress at user-specified extension or elongation

2. Tensile Yield Stress

3. Tensile Yield Strain

4. Tensile Strength at Rupture

5. Elongation at Rupture

ASTM D412 Test Method B

Test Method B also requires a universal testing machine. Method B is a less common test, requiring rubber ring samples. When beginning your testing, set the rate of spindle separation 500 +/- 50 mm/min (20 +/- 2 in./min). Start the test machine and record the force and corresponding distance between the spindles. When the specimen breaks, measure and record the ultimate (breaking) elongation and the tensile (force) strength.

Equipment and Software Required

Test Method A & B of ASTM D412 specify a test machine with at least 30 inches of travel and a test speed to 500 mm / min (20 ipm). TestResources provides special ASTM D412 test software. Our D412 software performs stress calculations as various elongation points and also does multi-test statestical analysis. The software makes testing for ASTM D412 simple. By means of our extensive testing expertise and modular product design, we will help configure the testing solution that is right for you. Give one of our application engineers a call today for help with creating the best budget and testing plan according to ASTM D412.

Recommended Rubber Elastomer Test Machine

Our Model NG-101, Double Column Universal Tensile Tester with Extensometer

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

ASTM D412 Kauçuk Çekme Test Makinesi, Kauçuk Elastomer için Çekme Mukavemeti Testi

Marka:

SKU: CM-RR64F

Kategori: Analiz - Test

Güvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.