This all-new design, together with our latest high-tech control system, improves quality of winding and reduces machine maintenance to a minimum.

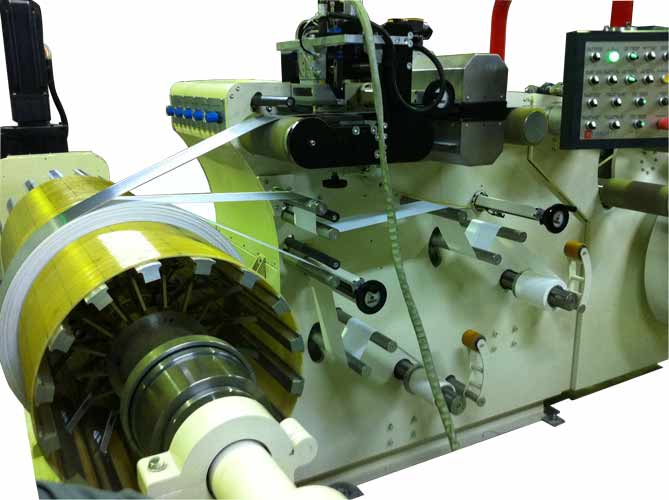

strip foil coil wound cast resin transformer Heavy duty coil winding machine for strip wound foil

One of the latest developments at Erasan is the range of foil winding equipment, with high-tech control features, improving quality of winding and reducing maintenance to a minimum.

Primarily used for winding of Cast Resin / Air Cooled transformers, the machines shown below are some of those already delivered, along with concept drawings showing a basic machine layout.

There are various configurations possible, with coil widths up to 2.3M with a winding area of 1.8M. This allows winding of a wide range of transformer sizes and number of strips as required.

The “state of the art” CNC with colour touch screen, precision servo motor drives, and bespoke software provide continuous control and monitoring of all of the process parameters, together with the capacity to store thousands of programs.

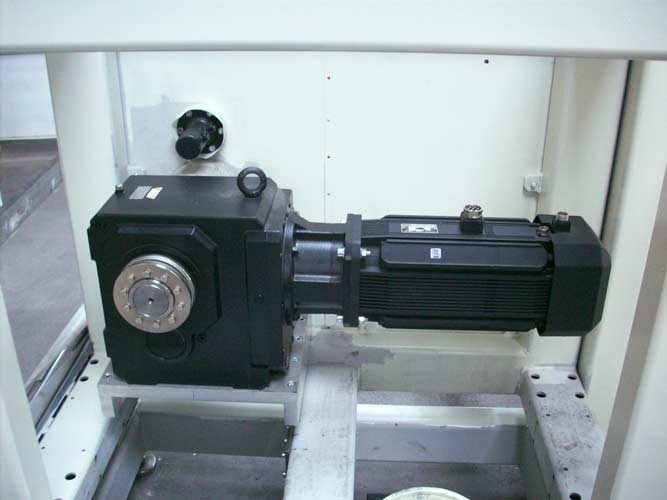

Heavy duty coil winding machine series winding head driver motor

High powered Parker servo motors with integrated gear box and drive systems.

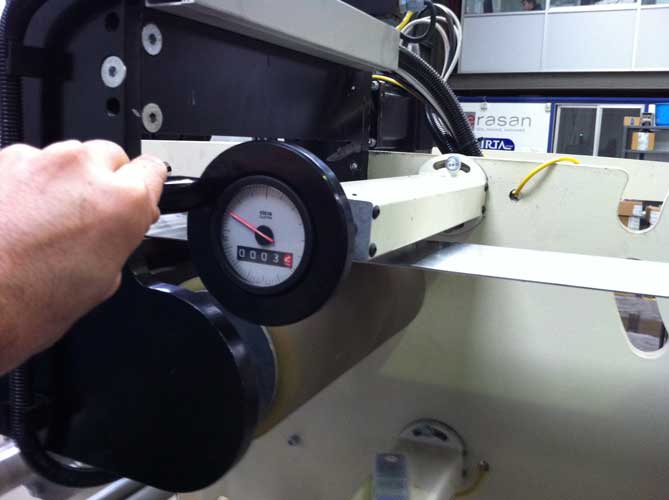

foil edge sensor Heavy duty coil winding machine series

Each mandrels foil or insulation has independent traversing system, with closed loop feedback from edge sensor, providing perfectly aligned coils

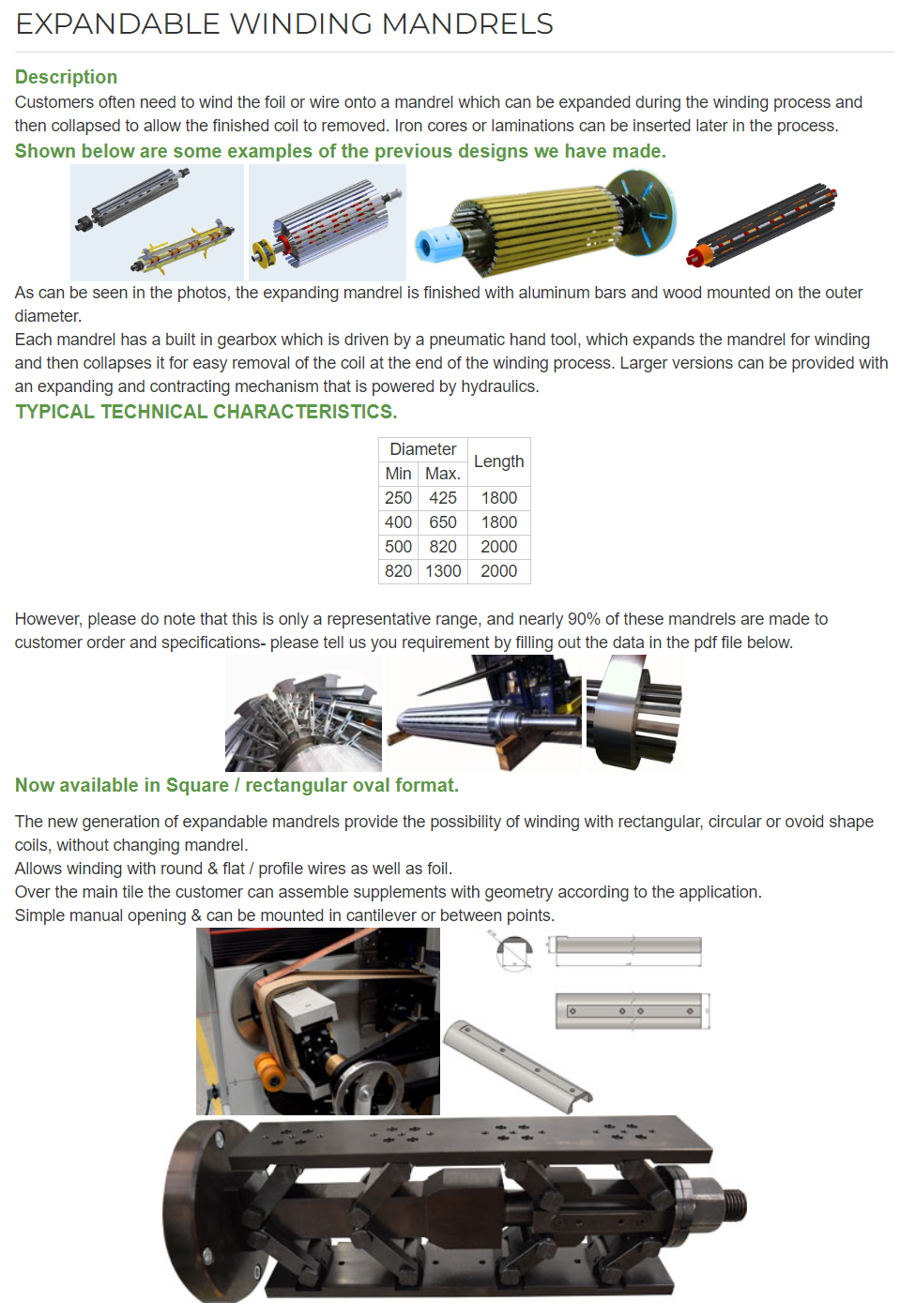

expanding mandrel hydraulic pump – Heavy duty coil winding machine series

Various automatic functions and processes can be added to the machine according to the user’s requirements.

Shown here is a cold pressure welding station, used for fixing the terminal leads “in-line” during the winding.

Standard specifications can be modified according to customer requirement.

Torque at max. Speed (Brushless motors):

2.500 Nm

Max winding length (foil width):

25 mm upto 150 mm (other types available on request)

Foil Thickness min. and max (Aluminium):

0.1 – 1.5 mm

Foil Thickness min. and max (Copper):

0.1 – 1.2 mm

Max coil weight:

2000 Kg

Maximum distance between points:

2300 mm

Max coil width:

1800 mm

Number of conductor de-reelers:

1 or 2

Number of insulation de-reelers:

1 or 2

Conductor Foil materials:

Copper or Aluminium

Insulation de-reelers Shafts:

Expandable (pneumatic open/close action)

Conductor de-reelers Shafts:

open/close action- Pneumatic <600mm; Hydraulic >600mm

End filler:

Strip paper included

Welding system:

Tig is standard for this style of winding.

(optional – Cold pressure welding)

Electrical supply:

3 x 400 + GND + Neutral

Air pressure:

6 Bar

User interface:

12inch (304mm) touch screen industrial PC / access controller

Max. No. of programmable windings:

1000 (unlimited with SD card)

Max. No. of windings per coil:

200

Type of programming:

CNC