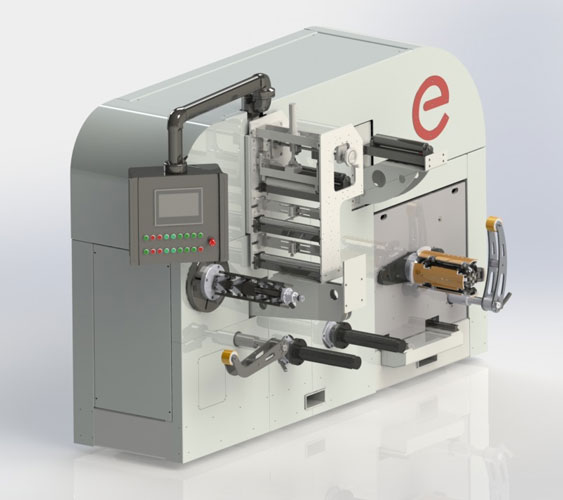

This all-new design, together with our latest high-tech control system, improves quality of winding and reduces machine maintenance to a minimum. Heavy duty coil winding machine series

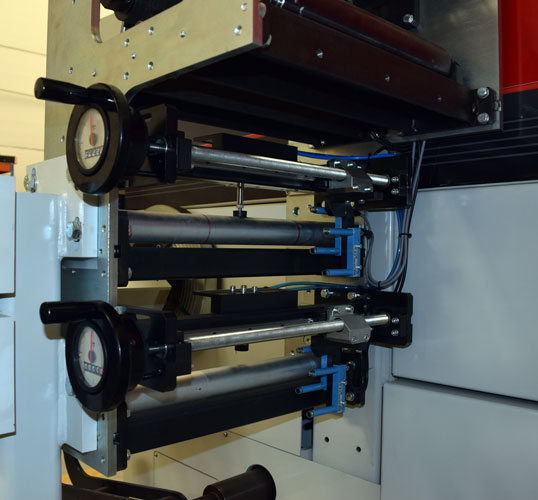

The foil and insulation de-reelers are provided with an automatically controlled brake system, which applies a constant tension to the materials during the winding process.

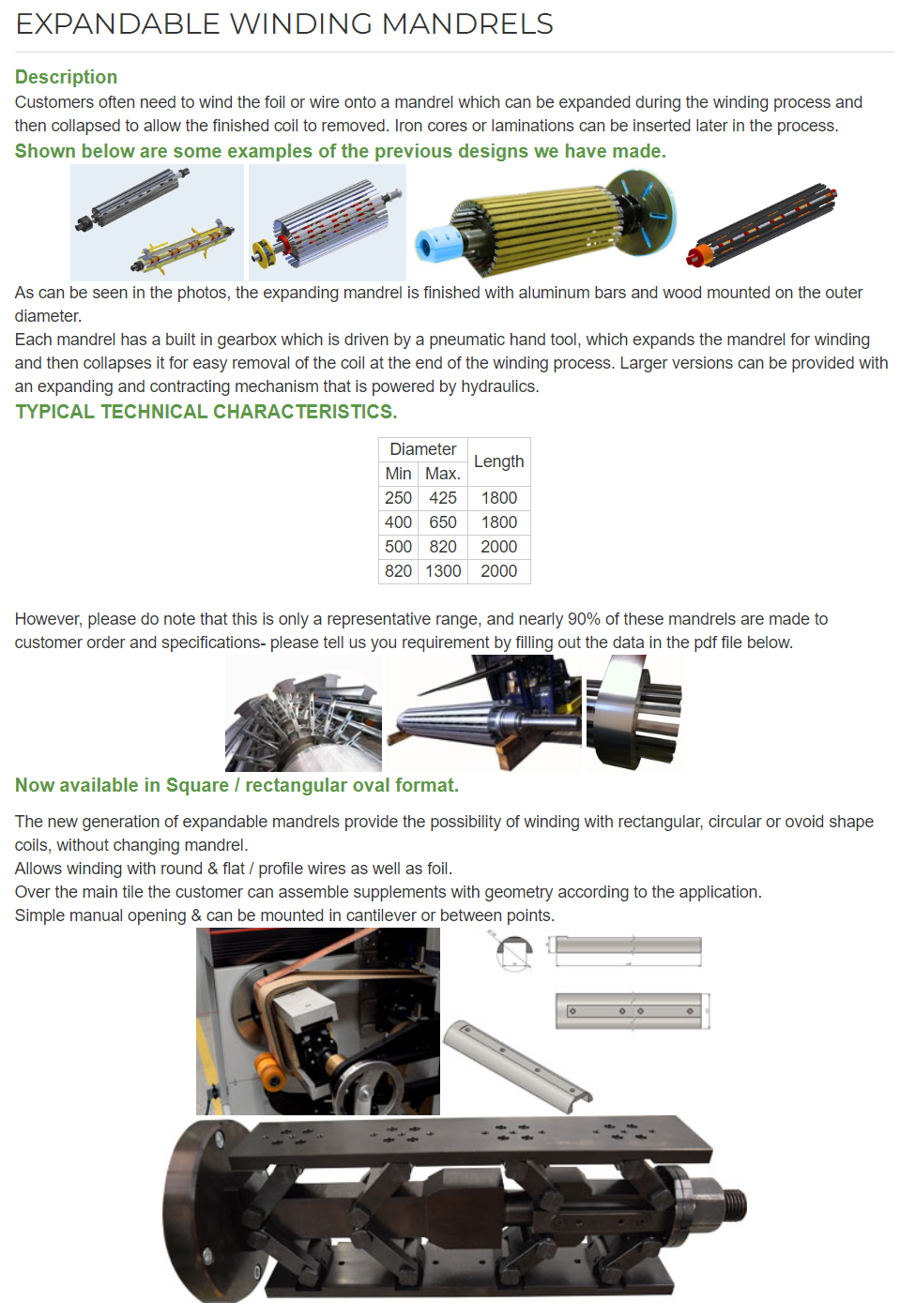

The winding unit is equipped with a pressure roller system and the machine is supplied with two expanding mandrels for the copper foil and two for the paper insulation.

The “state of the art” CNC with colour touch screen, precision servo motor drives, and bespoke software provide continuous control and monitoring of all of the process parameters, together with the capacity to store thousands of programs.

There are various configurations possible, up to 500mm width. Compact machine foot print and easy access for the operator help in easy winding of primaries reducing production cycle times.

A typical machine includes:

Heavy duty coil winding machine series

adjustable independent sensors are using in a closed loop feedback system to align each paper and foil..

Heavy duty coil winding machine series

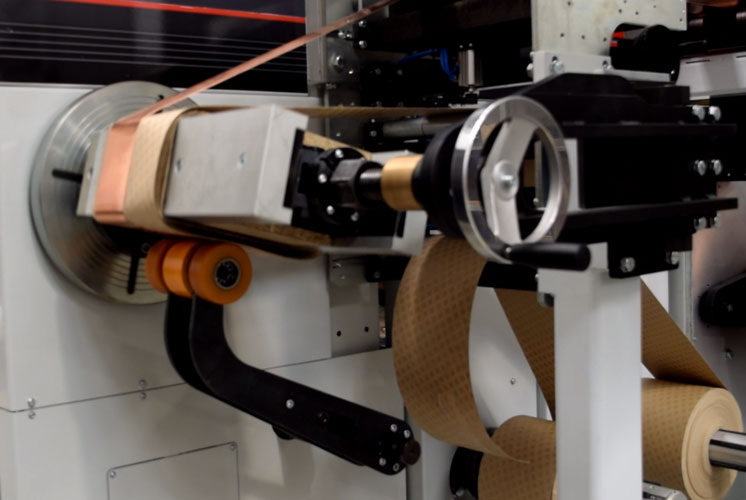

Expanding mandrels are designed open ended to allow easy access for fast supply spool changeover.

Heavy duty coil winding machine series

Foil press arm aids the operator at start end end of winding to keep tension on the foil.

A typical standard specifications shown below, however this can easily be modified according to customer requirements.

Torque at max. Speed (Brushless motors):

2,150 Nm

Maximum Speed:

40 Rpm

Max Winding Dia.:

800 mm

Max winding length (foil width):

300 / 400 mm (other types available on request)

Foil Thickness min. and max (Aluminum):

0.4 – 1.8 mm

Foil Thickness min. and max (Copper):

0.3 – 2.8 mm

Max supply spool weight:

250 Kg

Max finished coil weight:

400 Kg

Max finished coil OD:

550 mm

Number of conductor de-reelers:

1 or 2

Number of insulation de-reelers:

1 or 2

Conductor Foil materials:

Copper or Aluminum

Insulation de-reelers Shafts:

Expandable (pneumatic open/close action)

End filler:

Strip paper included

Welding system (optional):

Cold pressure welding / Tig

Foil De-burring system:

3 roller system, or Cleaning foil device for CPW

Electrical supply:

3 x 400 + GND + Neutral

Air pressure:

6 Bar

User interface:

12inch (304mm) touch screen industrial PC / access controller

Max. No. of programmable windings:

1000 (unlimited with SD card)

Type of programming:

CNC

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

Lv Transformatörler İçin Kompakt 300Mm Genişliğinde Folyo Sarma Makinesi Serisi

Marka:

SKU: CM-45N9Y

Kategori: Elektrik - Elektronik

Güvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.