Mochi Making Machine

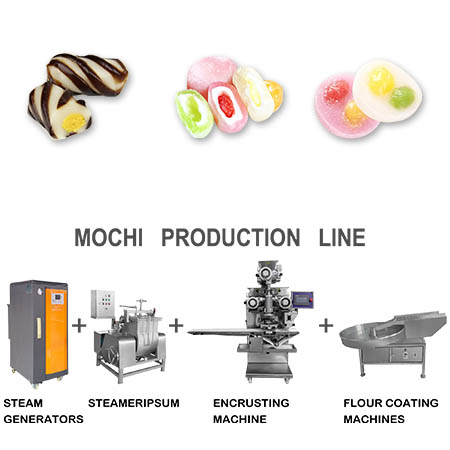

Mochi Making Production Line Description:

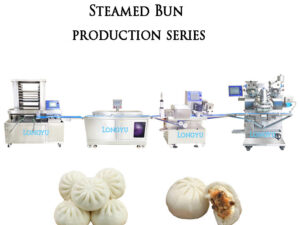

Mochi making production line is mainly composed of these machines: mochi dough making machines, mochi encrusting machine, and powder coating machine, the most important of which is the mochi making machine.

To make mochi or ice cream mochi, the most important thing is to make the mochi dough. If you want the taste of mochi to be soft and elastic, it is best to choose a mochi dough steamer to make mochi dough. In order to match the output of a mochi making machine, we recommend a 75L mochi dough steamer.

It’s very easy to operate the mochi dough steamer. All that needs to be done manually is to pour the ingredients(mainly glutinous rice flour and water) into the machine, and the rest can be done by the machine. The machine provides steam to steam the mixture while stirring continuously, and then the mixture gradually becomes elastic dough, saving a lot of labor and time!!

The next machine is mochi making machine. The standard type has two hoppers, one is for mochi dough, another is for filling. After putting the mochi dough and stuffing into the hopper, the screws in the hopper pushes the them forward, extrudes it through the extrusion mold, and cuts it into small pieces of equal weight by the cutter.

The most common mochi is with one skin and one filling. But by changing the molds, our mochi maker machine can make double-filled mochi, double-colored mochi, long strips of mochi, etc.

After years of research, Longyu Company has launched several other models of mochi machines. such as SV-208A, SV-380, SV-180…

Sv-208 mochi making machine has 3 hoppers, which can make mochi with 3 colors, like mochi with double color skin, or with double fillings. for model sv-208, the filling should be soft and thick, such as ice cream, red bean paste.

If customers want to add large chunks of pulp to mochi dough, we highly recommend the SV-380 model, which can protect the pulp intact without being crushed and turned into juice.

We all know that the skin of mochi is very sticky, and it needs to be coated with a layer of flour, otherwise it will stick to our hands. At this time, the powder coating machine is used, and the mochi is dropped into the rotating disk through the conveyor belt. After evenly coating the powder, filter out the excess powder by climbing device. Greatly save time and labors!

As for the forming part of making mochi, just the 3 machines are required. if customer want to make ice cream mochi, another machine is needed–freezer. if the output capacity is small, freezer is enough. if the capacity of machi customer wants to make is large, we suggest frozen tunnel, which we can provide!

Mochi Making Production Line Parameters

Mochi Dough Making Machine

Machine Size: 110*102*141cm

Machnie weight: 350KG

Power: 1.5KW

Voltage: 220V 50/60Hz Single Phrase

Capacity: 75L

Mochi dough: 70kg

SV-208A Encrusting Machine

Model: SV-208A

Machine Size: 168*86*170cm

Machnie weight: 360KG

Power: 1.75KW

Voltage: 220V 50/60Hz Single Phrase

Capacity: 60-110pcs/min

Product Weight: 10-270g

Powder Coating Machine

Machine Size: 187*110*102cm

Machnie weight:180KG

Power: 1.2KW

Voltage: 220V 50/60Hz Single Phrase

Capacity: 90-100pcs/min

Product Weight: According to the shaping speed

Mochi Encrusting Machine Details

Feasures

304 stainless steel, food grade material, durable and easy to clean.

High speed. the max speed can reach 120 pcs/min, faster than others.

Small weight error, about within 1g, stable product weight.

PLC intelligent touch screen, easy to operate for beginners.

Famous electric components, OTG motor, Delta PLC & inverters, make the machine operational performance more stabler.

Can save the production data of 99 products, just need to adjust the parameters one time for single product.

Various kinds of products can be made, more than 100.

Many devices and molds can be choose, very flexible.

12-month warranty.

Detailed instruction manuals, training videos.

8-2=?