Mooncake&maamoul Production LineAutomatic mooncake making machine consists of automatic encrusting machine, stamping machine,and automatic tray arranging machine.The mooncake machine can make different kind shapes and sizes of mooncake by change moulds.It is ideal for the production of mooncakes with different filling , chocolate biscuis,filled kubba, filled maamoul, arancini ,stuffed rice balls, croquettes, meat, fish or vegetable balls, date maamoul,Kibbeh,Coxinha and more.It can make 4000-6000 pieces product per hour ,by channging food mould ,you can make different food.There are other machines that can also do this product, such as SV-280, SV-180, SV-198, SV-380, etc.

Description

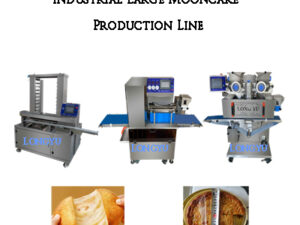

Mooncake Making Machine Production Line

The moon cake production line includes an encrusting forming machine, a moon cake stamping machine and a high-speed arranging machine. The filling machine is suitable for the production of moon cakes with various fillings. The fillings and dough are uniform and smooth, the specifications are uniform, the materials are not sticky, and the noodles are not sandwiched. The moon cake forming machine can customize various moon cake splint molds, which are non-sticky materials and uniform in forming. The high-speed stamping machine, material sensing, will not affect the signal transmission of the plate placement due to the obstruction of debris. Different placement methods can be realized according to the needs of customers, with a speed of up to 90 pcs/min.

Parameters:

SV-208 Encrusting Machine

product size:168*86*170cm

machine weight:320kg

machine power:2.5KW

machine voltage:220V

food weight:10-600g

production capacity:80-200pcs/min

Stamping machine

product size:170*52*116cm

machine weight:180kg

machine power:0.4KW

machine voltage:380V

food weight:10-250g

production capacity:0-130pcs/min

Arranging machine

product size:185*156*164cm

machine weight:280kg

machine power:1.75KW

machine voltage:220V

food weight:0-200g

production capacity:0-200pcs/min

Mooncake Machine Features:

For Encrusting Machine

1. The body is sealed, and the body and the electrical box are completely isolated, effectively avoiding damage to electrical components caused by oil dripping. The sealed design is also effective against rats.

2. After the optimization of the whole machine, the disassembly and assembly are simpler and more user-friendly. Workers can quickly locate the machine when installing, and new employees can also easily assemble with zero basis.

3. The product size, skin filling ratio, and speed can be adjusted through the touch screen; the streamlined intelligent touch screen system has a storage memory function, which can store the parameter values of ten products, directly call the parameters, and save the change when switching product varieties. Time cumbersome parameter input. The product grams can be fine-tuned at any time with one button.

4. Suitable for loose, loose and hard five-core fillings, as well as soft fillings. The inner cavity is coated with Teflon, which is anti-adhesive, wear-resistant, and the head is designed to reduce corners and corners and other dead corners that are difficult to clean. It is easy to clean, saving time and labor and labor.

5. Intelligent one-key synchronous speed regulation. Through PLC logic operation, the speed can be automatically switched between 20-90 pcs/min. Subtract the value that needs to be re-adjusted due to speed changes, reducing the scrap rate and saving time.

6. The standard powder sprinkling box device can automatically sprinkle powder synchronously.

For Stamping Machine

1. The internal components and the circuit board and the external working parts are completely isolated. The inside is fully enclosed. The surface slag, residue and oil can not enter the inside of the machine. The machine is still clean and hygienic for a long time. Improve the service life of inner parts. Anti-insect and anti-rat.

2. Innovative roller-type anti-skid mechanism of conveyor belt.

3. Compression type scraper + shovel plate, double scraper structure, good surface scraping effect, non-stick surface belt, conveyor belt is not easy to store surface. The round belt of the conveyor belt is made of special material, which is not easy to stick to the belt.

4. The rounding part is improved and optimized, the rounding is more stable, and the rear is equipped with double-row guide rollers, which effectively improves the yield.

For Arranging Machine

1. High-power servo drive, strong power and good stability

2. Simplify the operation interface, abandon traditional algorithms, abandon complex interface parameters, just enter the rows and columns, intelligently calculate the row and column distances, which are better understood and easier to operate.

3. The physical sensor will not block the photoelectricity due to debris or slag, which will affect the signal capture of the plate.

4. Multiple layouts, one-word layout, staggered layout, and single layout can be easily switched.

Detail Image:

Food Shows:

8-2=?