QM61 SMT pick and place machine 6heads 63slots Fully Automatic Pick&place machine SMT Assembly chip mounter

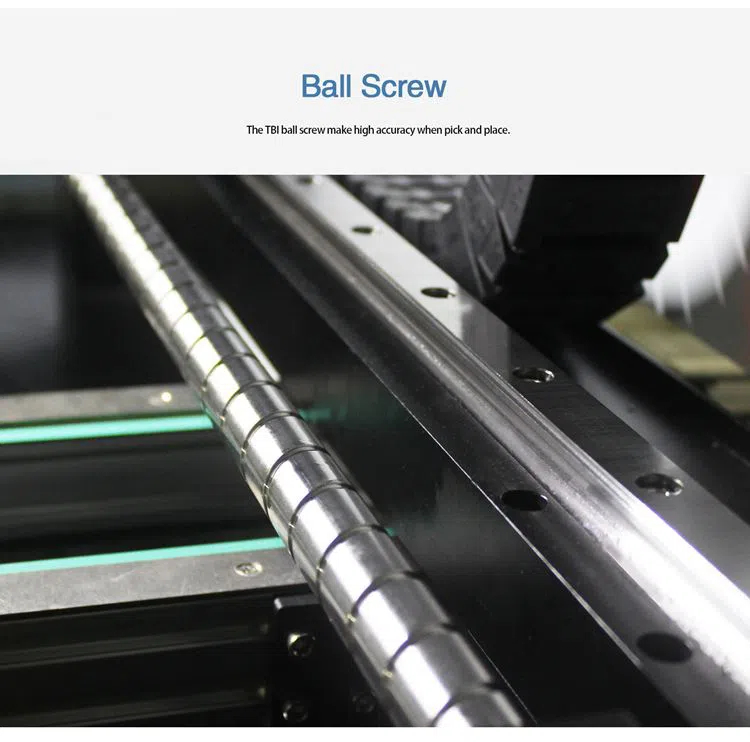

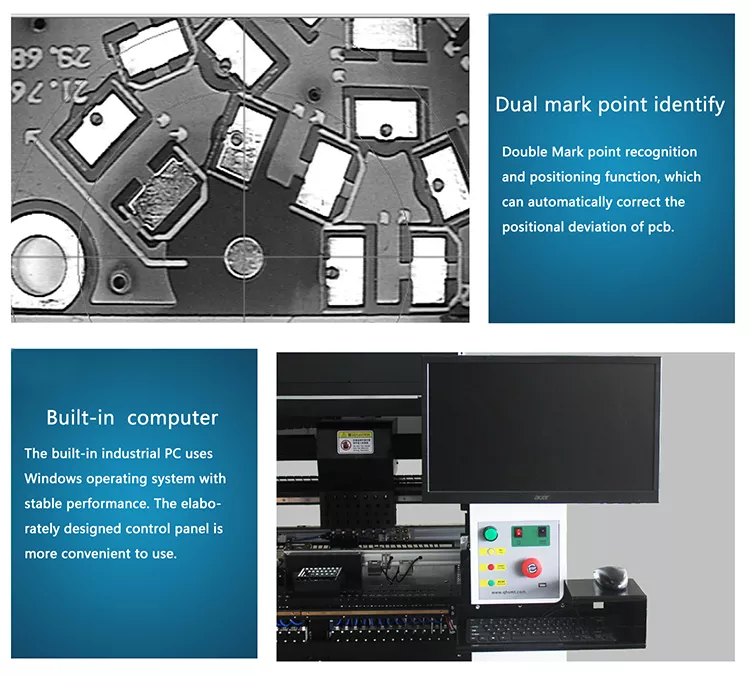

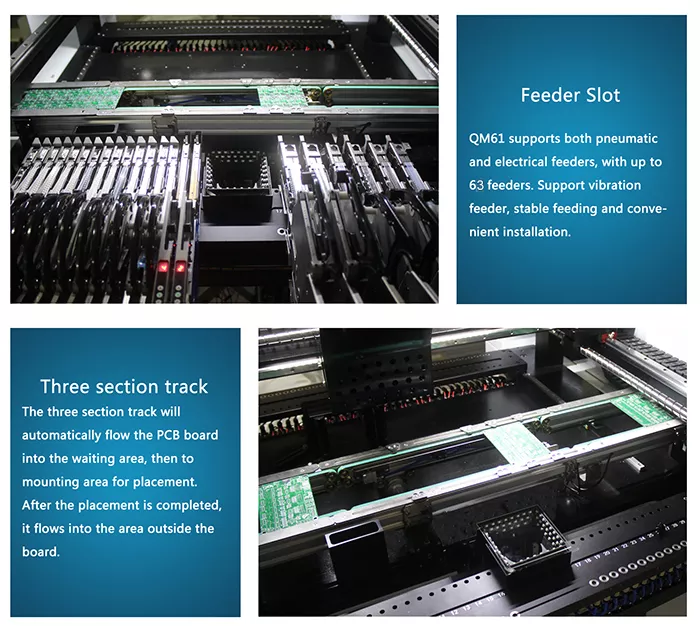

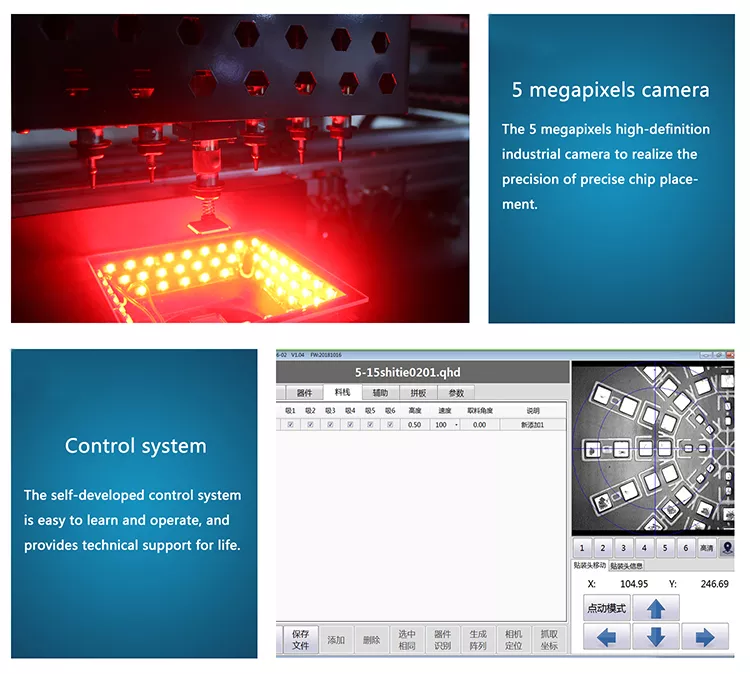

QM61 contains 6 heads,63 slots .The hardware including flying shot recognition camera,the Hiwin linear rail,the TBI grinding screw,the master computer ,triple stage transmission rail system.

Description

Inquiry

Description

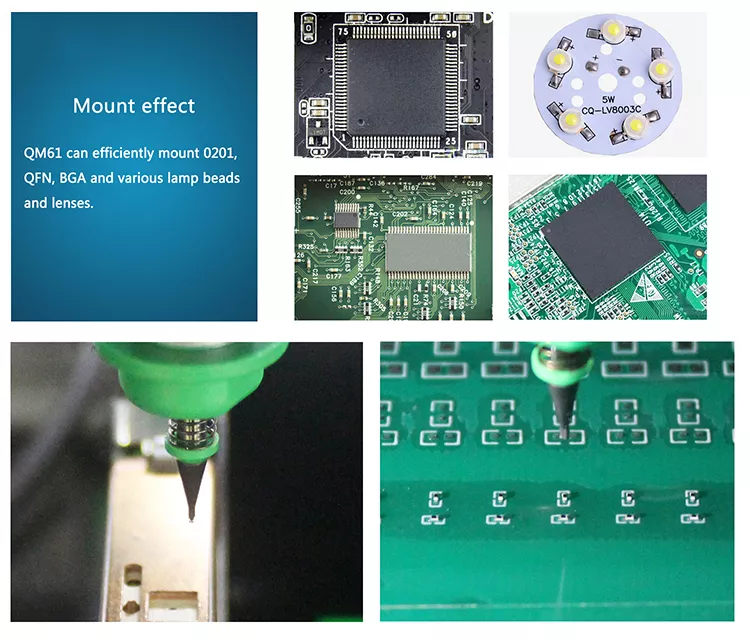

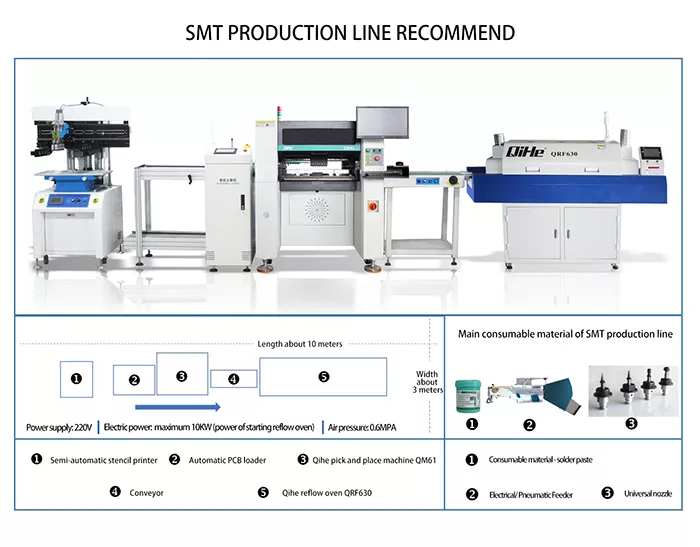

QM61 SMT pick and place machine is designed for mass production or R&D proofing purpose. It contains 6 heads,63 slots .The hardware including flying shot recognition camera,the Hiwin linear rail,the TBI grinding screw,the master computer ,triple stage transmission rail system.Upgraded the software functional such as the component library ,the visual surveillance,the safety alerts,the fault previously warning .QM61 pick&place machine can easily handling special-shaped components, BGA, 0201 inch package.QM61 chip mounter X Y axis adopts bigger Panasonic servo motor, speed up to 15000 components per hour (CPH),

ModelQM61Max applicable PCB size350*350mm/600mmMax xy moving range700*500mmMax z moving range20mmPlacement head quantity6Max mounting capabilityVision on: 11000pcs/hVision off: 15000pcs/hFeeder slots capability63 (YAMAHA Feeder is available)Applicable component Smallest size:0201 inchLargest size:22*22mmMax mounting Height15mmVisual camera Flight HD CCD cameraPowerabout1200WPower supply220VNet Weight814kgGross Weight900kgMachine Dimension1325*1120*1320mmPacking Dimension1360*1260*1460mmPacking size2.70CBM

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

QM61 SMT Pick and Place Machine 6Heads 63Slot Tam Otomatik Pick ve Place Makinesi SMT Montaj Çip Mounter

Marka:

SKU: CM-CG57S

Kategori: Elektrik - Elektronik

Etiketler: chip mounter, chip shooter, pick and place machine, pnp machine, qihe, QM61, smd, smt, SMT pick and place machineGüvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.