Description

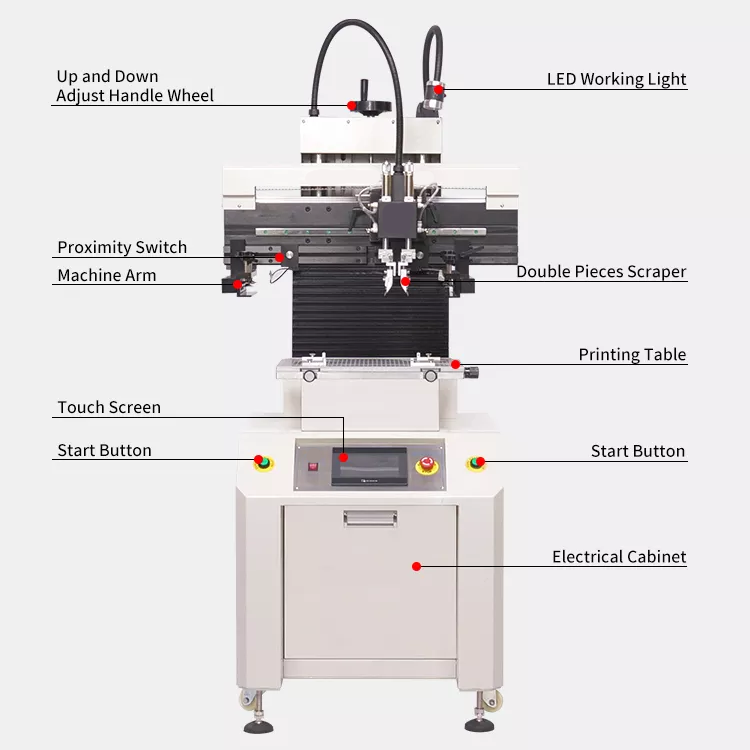

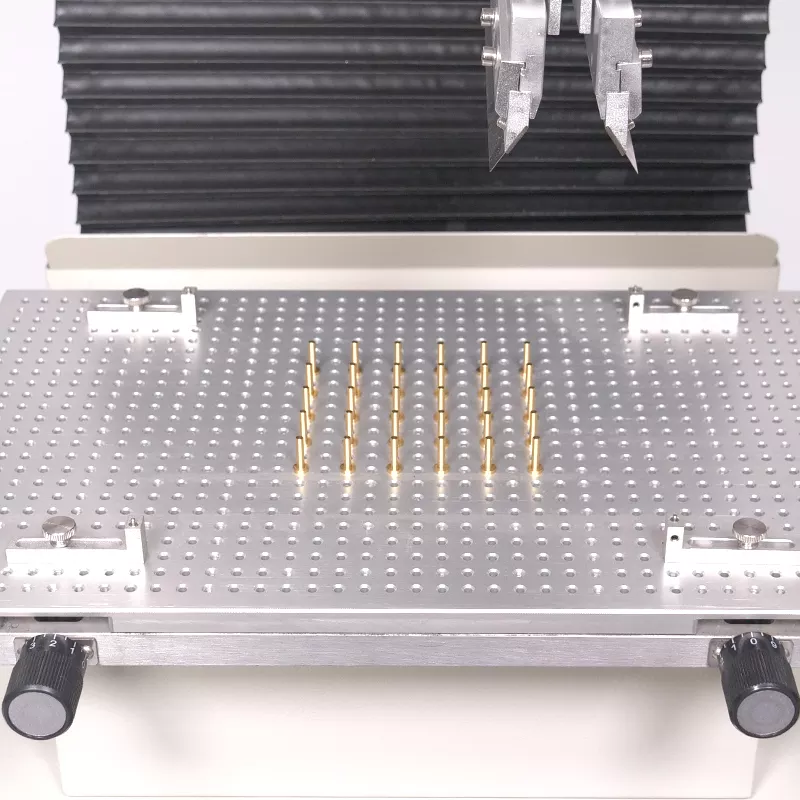

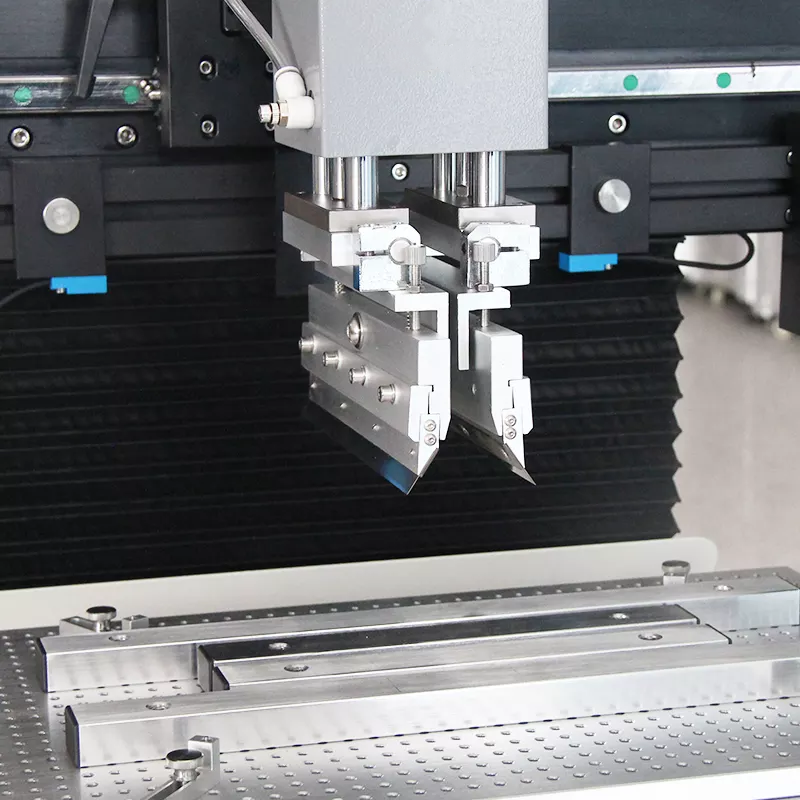

QP1068S high precise sem-automatically solder tin printing machine designed for 1.2 meters LED strip with high-quality speed control motor and linear guide rail and other precision accessories assembled, so that the scraper head printing smoother. Double-scrapers printing pressure can be adjusted by the up/down cylinder throttle valve, the lifting speed can adjust effectively avoid resonance.The printing head can be turned up 45o and fixed lock, convenient scraper loading and unloading and steel mesh cleaning, easy to operate.The printing head can be fixed after many directions, fixed convenient steel mesh in place, effectively ensuring the printing effect.The altitude of double-scraper of the printing head can be adjusted by adjusting the nut freely, so that the force between the scraper and the steel mesh can be controlled.The level of spacing between the printing table plate and the steel mesh, the adjustment of the scale of the precision spinner, and the scale number display.The robot arm moving range can be freely adjusted by the proximity switch, suitable for the requirements of different specifications of steel mesh.The printing table plate has high density snail bee hole with the use of thimble and positioning needle, free positioning, simple operation, quick replacement, and suitable for single-sided substrate and double-sided substrate production work.Electrical components using a microcomputer PLC combined with touch screen control, free choice of single or multiple printing and manual, semi-automatic and other modes.

modelQP1068Sprinting table acreage320*1250mmframe size370*470mm, 420*520mm, 550*650mm, 550*1550mmsubstrate size300*1230mmsubstrate thickness0.2-5.0mmfixation of printing positionpcb outer or pin positioningmicro adjust of table boardfront/back±10mm, F/L±10mmprinting precise±0.02mmmachine repeated accuracy±0.05mmminimum spacing0.35mmusing power supply220v 50/60Hz 100wmachine size1680*700*1650mmoutline packaging size2200*850*2120mmnet weight280kggross weight350kg

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

QP1068S Yarı Otomatik Şablon Baskı 1.2metre

Marka:

SKU: CM-ILNHT

Kategori: Elektrik - Elektronik

Etiketler: led strip, QP1068S, semi-auto, stencil printerGüvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.