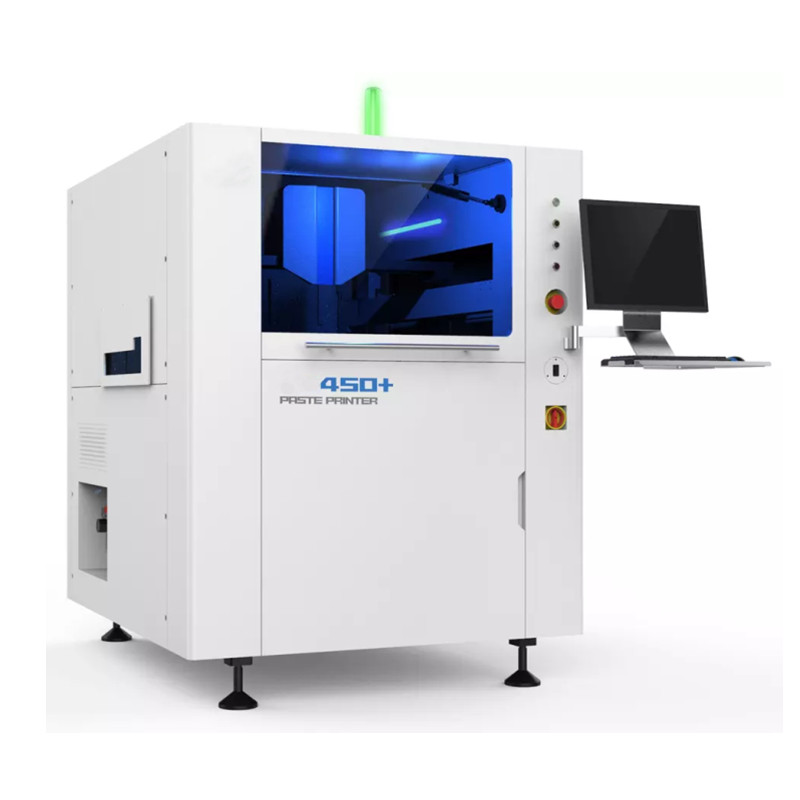

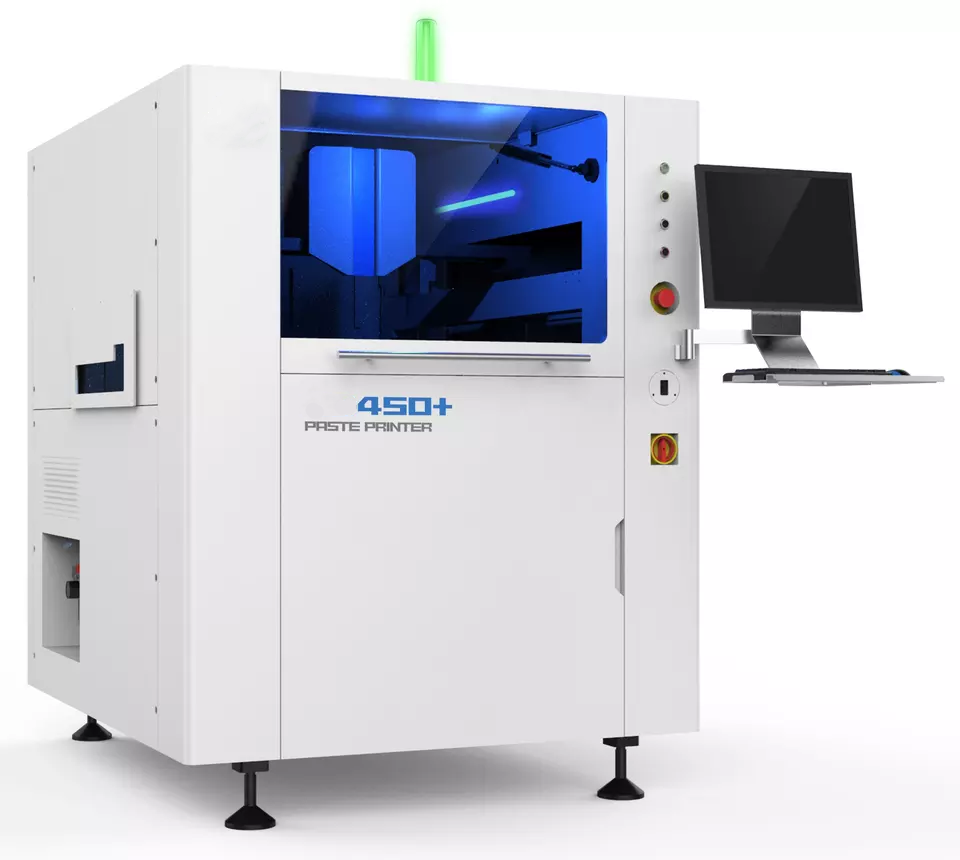

QP450+ automatic vision solder paste printer stencil printer machine screen printer machine

QP450+automatic soldering machine (fully automatic vision solder paste printer )stencil printer machine screen printer machine stencil printer .

Description

Inquiry

Description

QP450+automatic soldering machine (fully automatic vision solder paste printer )stencil printer machine screen printer machine stencil printer .The whole machine is fully controlled by servo system.Automatic pressure feedback system.Multifunctional image processing system.Precise PCB transportation system.Intelligent PCB holding device.Automatic steel mesh positioning module.Automatic and effective steel mesh cleaning system.User-friendly operation interface.

PCB ParametersⅠMaximum board size(X x Y)450mm x 350mmMinimum board size(Y x X)50mm x 50mmPCB thickness0.4mm~6mmWarpageMax. PCB ≤1%DiagonalMaximum board weight6KgBoard margin gapConfiguration to 3mmMaximum bottom gap20mmTransfer speed1500mm/s(Max)Transfer height from the ground900±40mmTransfer orbit directionLeft-Right,Right-Left,Left-Left,Right-RightTransfer modeOne stage orbitPCB damping methodProgrammable flexible side pressure, (Optional: 1,Bottom integral suction cavity vacuum, 2.Multipoint partial vacuum at the bottom; 3. Edge locking and Substrate clamping)Support methodMagnetic thimble, Equal high block,Vacuum suction cavity; Special workpiece fixturePrinting parametersⅡPrinting headLinear motor type close loop printing headTemplate frame size470mm x 370mm~737 mm x 737 mmMaximum printing area(X x Y)450mm x 350mmSquegee typeSteel scraper/Glue scraper(Angel 45°/50°/60° matching the printing process)Squegee length220mm~ 500mmSquegee height65±1mmSquegee thickness0.25mm Diamond-like carbon coatingPrinting modeSingle or double scraper printingDemoulding length0.02 mm – 12 mmPrinting speed0 ~ 200 mm/sPrinting pressure0.5kg – 10KgPrinting stroke±200 mm (From the center)Field of view6.4mm x 4.8mmPlatform adjustment rangeX.Y:±7.0mm,θ:±2.0°Benchmark point typeStandard shape benchmark point(SMEMA standard), solder pad/openingsCamera systemIndependent camera,upwards/downwards imaging vision systemPerformance parametersⅢRepetition precision of image calibration±15.0micron @6 σ,Cpk ≥ 2.0Repetition precision of printing±20.0micron @6 σ,Cpk ≥ 2.0Cycle time<7sProduct changeover<5minsPower supplyAC220V±10%,50/60HZ,15AAir supply4~6Kg/cm2, 10.0 Diameter of the tubeGas consumptionAbout 5L/minOperating systemWindows XPExternal dimension1140mm(L) x 1450mm(W) x 1480mm(H) (Without light,monitor and keyboard)Machine weightAround 1000KgTemperature and humidity control module(optional)Environment temperature23±3˚CRelative humidity45-70%RH4

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

QP450+ Otomatik Görüş Lehim Pastası Yazıcı Sabetçi Yazıcı Makinesi Ekran Yazıcı Makinesi

Marka:

SKU: CM-U6WWT

Kategori: Elektrik - Elektronik

Etiketler: automatic vision solder paste printer, screen printer machine, stencil printer machine,stencil printer,qp450+,qp450,Güvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.