Specification

No. of spindles

8

Wire size

0.02-0.5 mm

Max traverse width

85 mm

Winding spindle pitch

55 mm

Max bobbin diameter

50 mm – less if load unload system used

Winding spindle speed

18,000 rpm

Spindle position accuracy

+- 0.1°

Guide head drive motor

200W AC servomotor X , Y and Z axis

Max movement of guide head

X(left/right) 100 mm

Y(front/back) 75 mm

Z(up/down) 65 mm

Nozzle positions

0°, 90° or 120°

Max pin wrap speed

150 Turns / min

Control system

Windows interface PC with USB connector & DVD ROM

Interface

RS232 or USB

Touch screen

15 inch

Air supply

6 Bar

Power supply

single phase 220V +-10% 50Hz

Power consumption

3kwA

Weight

485 Kg

Dimensions (cm)

110(W) x 130(L) x 155(H) – excluding wire spool stand

8 spindle automatic coil winding machine

Click for larger image

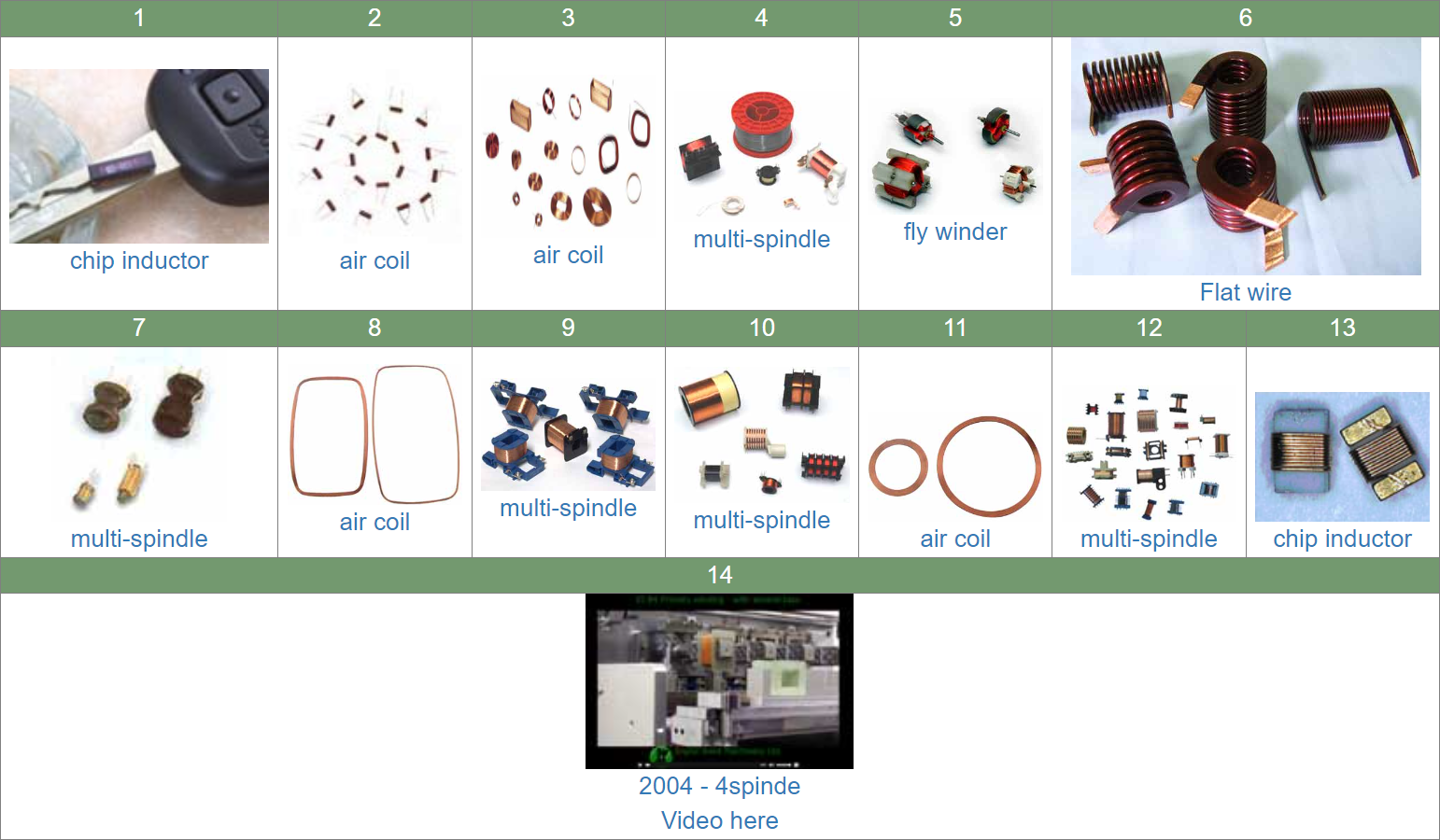

production examples from this coil winder

Description:

A high speed fully automatic coil winding machine with advanced PC control of multi axis servo systems, for winding inductive devices with fine wire in medium and large volume. Applications include relay coils, magnetic head coils, LCD coils, transformers, ignition coils, inductors, sensor coils, solenoids, and other bobbin-wound products.

Main features:

The wire guide movement can be freely programmed in all 3 axes (X, Y, and Z). Programmable nozzle movement through 0°, 45° and 90°angles enables pin wrapping on both radial and axial pins,

Wire cutting on bobbin pin, nozzle cut or by air nipper (method can be chosen by operator and setup in the program).

Simplified programming with teach-in programming system using 15 inch touch screen, Windows™ based graphical interface, industrial PC with USB, Ethernet network and DVD ROM facilities.

Easy to change tooling and machine set-up recalled from the onboard computer when changing product.

Fully CE compliant.

Options:

Air nipper for larger wire.

Load and unload shuttle transfer system.

Skeining (Wire twisting) unit.

Customised accessories to suit your application