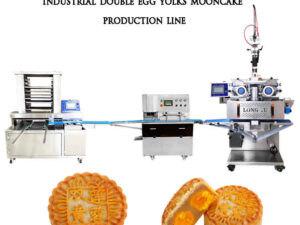

Bagel Machine Line

Bagel, doughnut-shaped yeast-leavened roll that is characterized by a crisp, shiny crust and a dense interior. Long regarded as a Jewish specialty item, the bagel is commonly eaten as a breakfast food or snack, often with toppings such as cream cheese and smoked salmon.

Let me introduce our lastest automatic machine line SV-209 Bagel Production Serie, which has 8 pieces of equipment that consists of dough mixer, dough conveying machine, dough pressing machine, dough dividing machine, main machine, pinching cutting machine, bagel forming machine and tray arranging machine. The max capacity is 1800 pcs/h.

Description

What exactly is a Bagel?

A bagel is made by first cooking it in water-very hot boiling water-for one or two minutes to lock in its flavor. Then it’s browned in the oven to create that hard, delectable crust. This process produces a dense, chewy roll with a crisp exterior, no doubt giving rise to the name “cement doughnut.” Of course, bagels have evolved over the years to include not only egg to make the roll a bit lighter, but also spices, herbs, and fruit to give added flavor.

The advantage of SV-209 Bagel Production Serie

The tipping bucket dough mixer can be used with the flour supply equipment to complete the dough mixing, then transfering to the dough spiral mixer;

The dough pressing machines is another major technological breakthrough made by the R&D department: it is composed of two sets of equipment, transfering, pre-pressing and quantitative cutting, which saves the work of manual division, transferring and carrying. Maitaining the high-level of automation between equipemnts.

After the dough is ready, it will be divided quantitatively and send to the pressing machine, the pressing machine will automatically roll and fold repeatedly until dough becomes ractangle shape in perfect texture and smooth.

The three-piece set of machine consists of main machine, pinching cutting machine and bagel forming machine. The main propose of this set of machine is to ensure each bagel weight and shape are the same, which has various kinds of moldings.

The tray arrangement system is the last procedure before the bread rise. First put the bread into the baking tray, and then move the baking tray to the trolley. The plate arranging machine is a new product developed last year. Its appearance takes the automation of the bagel production serie to the next level.

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

Güvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.