Specifications can be modified according to customer requirements.

Max Wire pitching:

99 mm

Max winding length:

350 mm

Max distance between points:

500 mm

Max winding Diameter:

350 mm

Face plate Diameter:

80 mm

Guider precision:

0.001 mm

Spindle resolution:

0.01 mm

Main shaft motor:

Servo – 6Nm at 3000 rpm

Guider motor (Brushless):

Servo – 1.4NM

Winding shaft speed:

0 – 3,000 / 6,000 / 9,000 rpm*

Electrical supply:

3 x 380Vca – 50Hz

Net weight:

250 kg approx.

User interface:

7inch (178mm) colour touch screen

Max. No. of programmable windings:

10,000 (per SD card)

Max. No. of windings per coil:

200

Type of programming:

CNC with colour touch screen

Torque and Speed

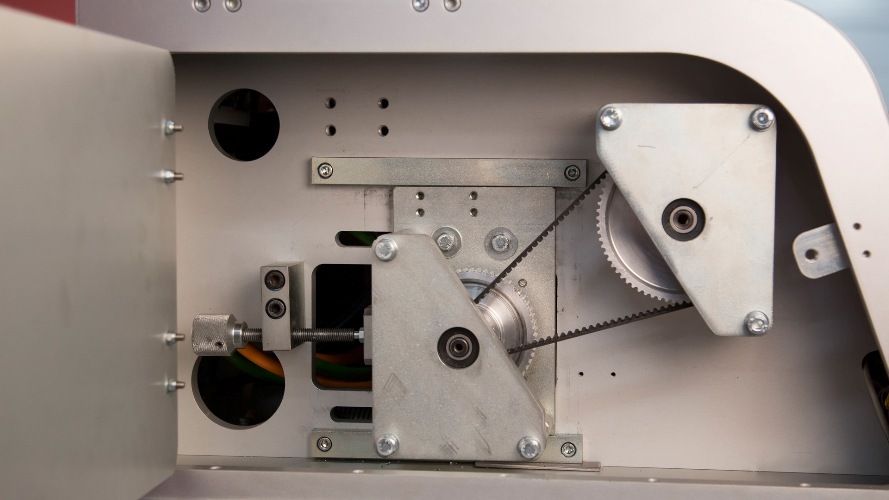

* There are three version of this machine, each having three belt positions.

Belt Position

G version – 3000 RPM

N version – 6000 RPM

R version – 9000 RPM

Speed (Rpm)

Torque (Nm)

Speed (Rpm)

Torque (Nm)

Speed (Rpm)

Torque (Nm)

1

3000

6

6000

3

9000

2

2

1500

12

3000

6

6000

3

3

750

24

1500

12

3000

6

Heavy duty coil winding machine series

Click for larger image

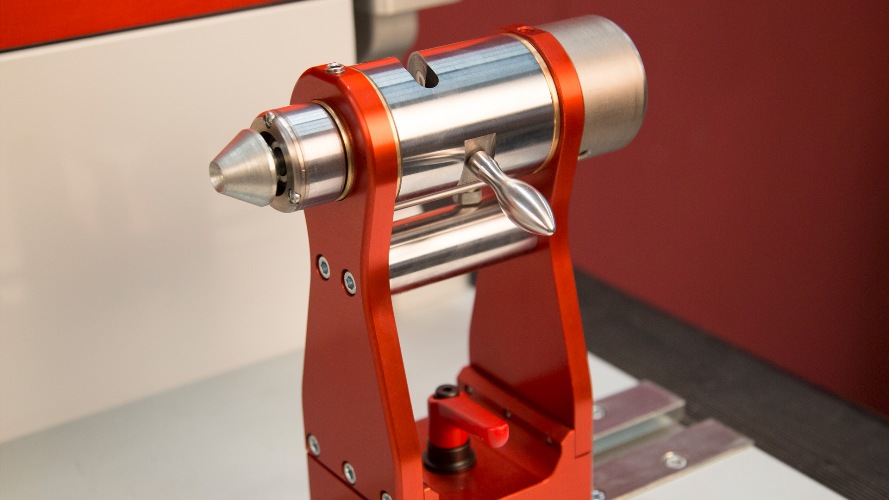

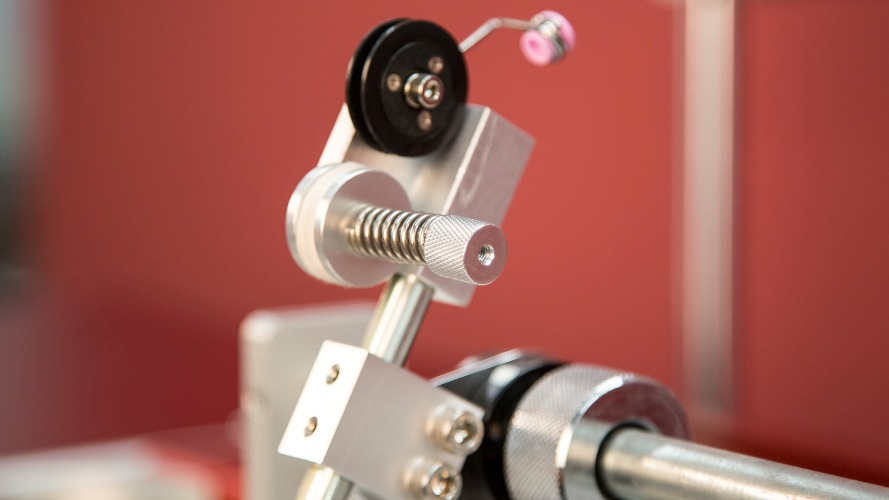

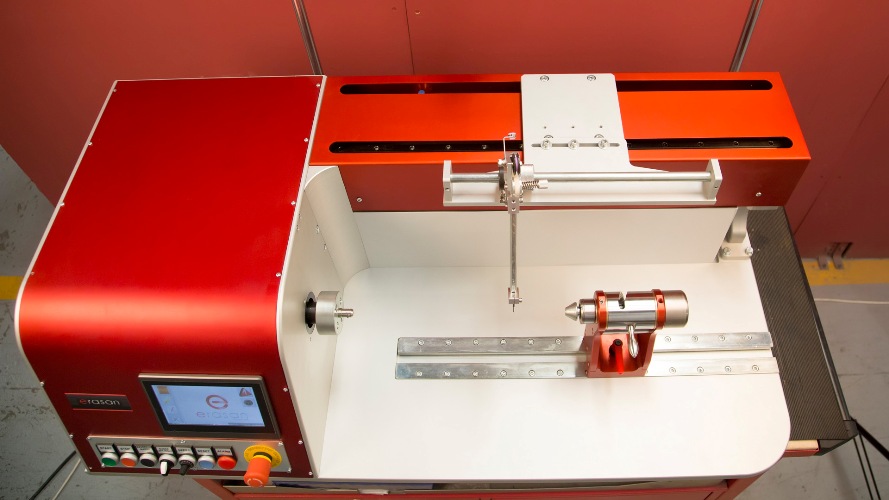

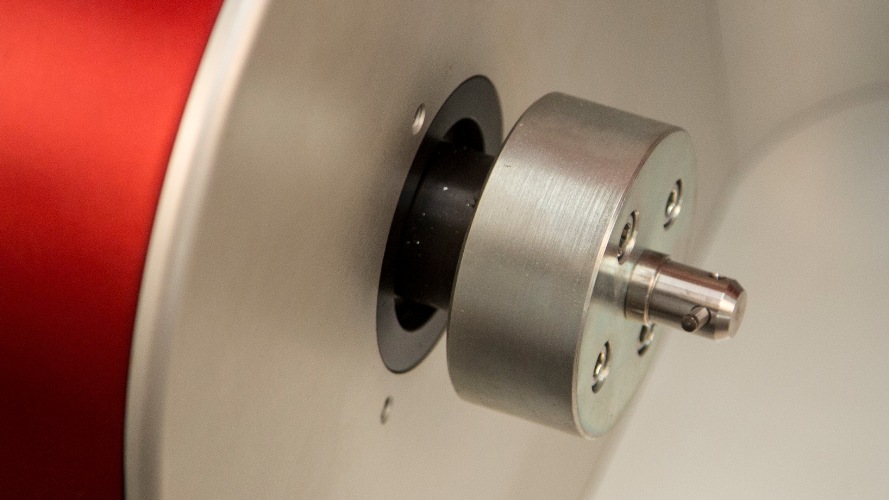

E-300 – Small sized bench Winding Machine; equipped with: –

Traverse head

Sturdy base

Tailstock – with security lock,

Guider system

& Safety shielded foot pedal.

Controlled by numeric PLC and electronic programming.

The applications of this machine is intended for the manufacture of solenoids, reactances, transformers, with capacity to make multiple windings and even distribution and power transformers.

There are various configurations of speed ranges, up to 9,000 rpm (depending machine version). This produces fast cycle time for high turn primary windings.

The colour touch screen provides a simple and intuitive programming system with graphical interface and on-screen help, allowing even the most complex windings to be programmed in short periods of time in the user’s choice of language. A foot pedal is provided so that the operator can control the machine manually if required.

Data storage is on a standard SD card, providing a quick and simple method of backing up programs on a PC.